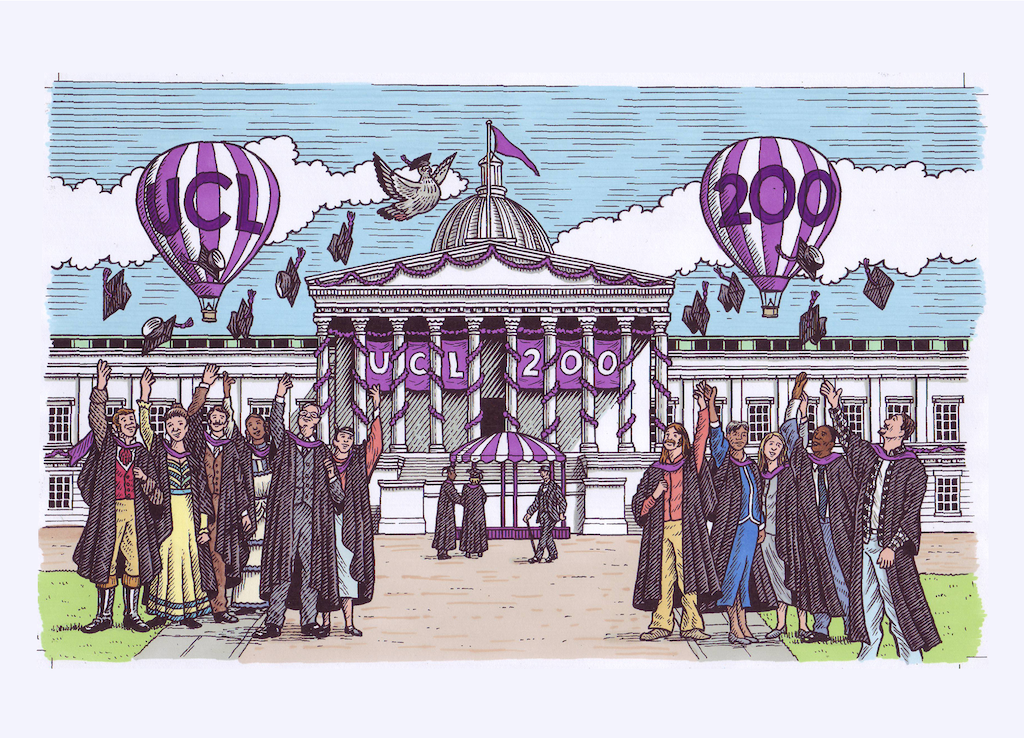

UCaLe - Brewed to commemorate UCL's Bicentennial

Founded 200 years ago, UCL emerged when London was the global hub of brewing - an industrial era dominated by fierce competition among the city's largest porter breweries. Porter, the dark precursor to stout, was a staple for workers and city dwellers alike, no doubt also enjoyed by some of UCL's early staff and students!

184 years on, as London's brewing heritage waned, UCL Psychology Lecturer Dr Keith Langley advised student John (Jack) Hobday to home-brew “to save some money on beer!”. Inspired, Jack teamed up with then flatmate Paul Anspach (a King's College London Philosophy alumnus), and in 2014 they founded Anspach & Hobday.

Twelve years later, we proudly present UCaLe, a light, fresh, English-hopped Bermondsey Pale inspired by the London workers who travelled to Kent each summer to pick hops. It features the hop variety Ernest, rediscovered and named after pioneering mycologist, Ernest Stanley Salmon (1871-1959), who worked at Wye College, University of London.

This year, as UCL marks its 200th anniversary and our brewery turns 12, we're thrilled to say we are now London's biggest porter brewery, thanks to our renowned London Black. A historic milestone we hope our academic forebears would applaud.

To find out more about UCL's bicentennial plans visit the UCL200 website and please visit UCL's Institute bar to enjoy UCaLe on campus.

Please enjoy responsibly!

John (Jack) Hobday, BSc (Hons) Psychology 2010, UCL

Drink London Black! Drink London Black! - Carol of the London Black.

Drink London Black! Drink London Black!

Our beloved London Black gets its own Christmas Carol and Music Video! Captured in the studio and on the night at our famous Christmas Carols evening, this re-imagining of a Christmas classic is as smooth on the ear as London Black is on the palate.

Huge thanks to Matt The List and his Christmas Choir for lending us their voices, and to Harry Wrigley for capturing the magic.

Head over to the webshop to stock up, crack open a can and sing along to your new favourite Christmas Carol! Yummy Yummy Yummy Porter!

Credits:

Video Filmed and Produced by Ellie Edmonds and Anspach & Hobday

Original Composer: Mykola Leontovych

Lyrics: Matthew Hickman, Anspach & Hobday

Producer/Engineer: Harry Wrigley

Performers: Matt The List’s Christmas Choir, Anspach & Hobday

Hop Pickers’ Harvest (Green Hopped Pale)

The Hop Pickers’ Harvest is our first ever Green Hopped beer, brewed exclusively with freshly picked Ernest hops, grown at Hukins Hop farm in Tenterden, Kent.

The freshness of the hops is right at the fore, with intense, bright tropical and citrus fruit aromas jumping out of the glass, along with subtle notes of anise and a unique, fresh floral character.

It’s easy to forget that beer is, at its heart, an agricultural product. It's especially easy to forget this if you brew on a South London industrial estate. Raw materials arrive on pallets, in boxes, vacuum packed in mylar, wrapped in plastic, and are available all year around, often at a single day's notice. Whilst convenient, and indeed essential, this belies the true nature of beer and the ecosystem upon which it depends. A recent number of visits to the hop gardens of Kent in preparation for our first Green-Hopped beer have brought this into sharp focus.

It is curious perhaps, that cities such as London have historically been, and arguably remain, the epicenters of brewing cultures, quite separate from the farms upon which they depend. There are good reasons for this including transportation and access to ingredients, access to the market and consumers and the heavy dependence on industrial resources and labour. This is in stark contrast to wine, whose production is virtually inseparable from land and settings from which its grapes are produced.

However, the dependence remains. Without the farms, and more importantly the farmers, we brewers are clearly nothing. The generational knowledge and experience, and enduring dedication on display at hop farms such as Hukins is nothing short of inspiring. It serves as an important reminder that a beer is truly made long before the brewer even has their boots on.

In the case of London at least, a connection to hop growing farms did remain, with families traveling to Kent at the end of summer for ‘Oppin Season. Often setting up fully fledged, yet temporary communities, the Londoners would set to work, deftly cutting the bines from the wires and carefully picking the cones, ensuring each one remained in tacked and in prime condition for its use in the brewhouse. This is the history that both the Hop Pickers’ Pale and the Bermondsey Pale aim to celebrate.

(On a personal note, my Grandmother was born and raised just a few hundred meters from our Bermondsey Arch, so imagine my disappointment when I learned that she did not spend her summers picking hops, as many of her neighbours likely would have done. No eye on the narrative, ey!)

On to the beer itself. The Hop Pickers’ Harvest is our first ever Green Hopped beer, brewed exclusively with freshly picked Ernest hops, grown at Hukins Hop farm in Tenterden, Kent. The freshness of the hops is right at the fore, with intense, bright tropical and citrus fruit aromas jumping out of the glass, along with subtle notes of anise and a unique, fresh floral character. The beer is as balanced and drinkable as the year-round release, but the freshly picked green hops offer it its own unique identity, also imparting a touch more bitterness.

With only a matter of hours between the hops being picked and being loaded into the brew house, this beer is a truly unique expression of the Ernest hop, only achievable for a fleeting moment once a year.

Our brewhouse isn't designed to accommodate whole cone hops, much less green hops (which require about 6 times the quantity by weight when compared to kilned hops), so we were unsure as to how their presence would translate in the finished beer. Any concerns were well and truly allayed upon taking the first samples from the tank. The beer is as bright and vibrant as any traditionally hopped beer we’ve brewed, which is made all the more surprising by the fact that Hop Pickers’ Harvest is not dry-hopped. In addition to the dominant fruitiness of the beer, there is another dimension to it; a freshness, a floral, spicy and almost leafy character to it that I have not experienced when using kilned and pelletised hops. It is this character that places the beer right from where it came, the verdant hop gardens of Kent.

As a brewery, we typically spend this time of year focusing on our Oktoberfest offering, which involves brewing a number of classic German styles beers and putting on some sort of lederhosen-clad event. Whilst we will no doubt continue this adopted tradition, I wonder if from now on we will also focus our attention a little more closely to home.

The harvest offers us a unique opportunity to brew a truly special beer. It also affords us a moment to reflect upon all that we depend on; the seasons, the land, the farmers, and of course, the Hop Pickers!

Paul Anspach

The full illustration, by Alan Batley.

Shop here

The Pineapple Gose - Collab with Maldon Sea Salt

Aromas of freshly sliced, fleshy pineapple are achieved not only by the addition of 100kg of pineapple juice, but also by the use of the intensely fruity Bru-1 hop. Coriander seeds add gently aromatic notes of sweet spice. A delicate acidity keeps the beer bright and fresh, while a touch of salt on the finish adds balance and drinkability. A humble reimagining of a classic German style.

https://www.anspachandhobday.com/shop/the-pineapple-gose